Forge River Installation of Low-Pressure Sewer – Contract 4 South

Location:

Mastic, NY

Client:

SCDPW

Contract Value:

$13.3 Million

Project Dates:

September 2022 – December 2024

- Testing Of 35,000 LF of LPS

- LPS Diameters Ranging From 1.5 to 6 Inches

- 671 Building Connections

- 69 Precast Concrete Structures

PROJECT OVERVIEW

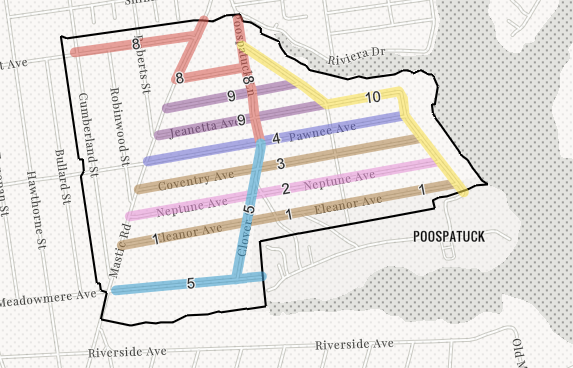

The contract scope of work encompasses the installation and testing of over 35,000 linear feet of low-pressure sewer piping, with diameters ranging from 1.5 inches to 6 inches. Additionally, 671 building connections will be installed and rigorously evaluated to ensure compliance with quality standards. The project includes the installation of 69 concrete precast structures, complete with interior piping to support system functionality. For roadway restoration, more than 10,000 tons of asphalt will be laid for comprehensive curb-to-curb resurfacing of Town roadways, achieving a high standard of durability and finish.

WHAT MADE THIS JOB COMPLEX

This project’s complexity stemmed from its blend of routine operations with new, specialized work—specifically, Horizontal Directional Drilling (HDD), a method not previously undertaken by Posillico. While the technical demands of HDD presented an internal learning curve, the main challenges centered on resource allocation and effective project management. The PM team and site crews had to quickly adapt, developing new competencies in HDD while maintaining high standards in existing services. This required enhanced coordination, specialized staffing, and robust support structures, ensuring the successful integration of new techniques within the project’s scope.

HOW POSILLICO SOLVED IT

To address the unique demands of Horizontal Directional Drilling (HDD) on this project, we strategically sourced experienced manpower from trusted industry partners, bringing onboard professionals with proven HDD expertise. Additionally, we invested in specialized equipment, retrofitting it to meet the specific requirements of the job site. This proactive approach not only bolstered our team’s capabilities but also optimized our equipment to handle the project’s complexities, ensuring high-quality results and a seamless integration of this new operation.