Bergen Point WWTP Outfall Replacement Project

Location:

West Babylon, NY

Client:

Suffolk County DPW

Contract Value:

$187 Million

Project Dates:

2018 to 2021

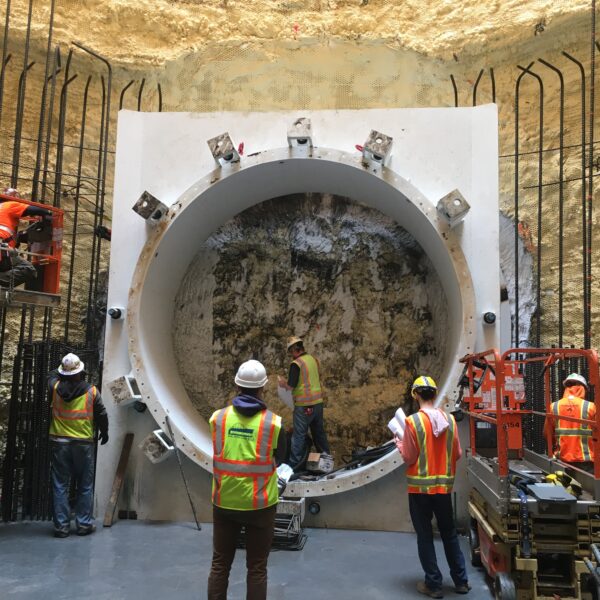

- TBM tunneling of app. 14,200-foot tunnel, 10 foot wide, 100 feet below the bay, lined with precast segmental liners

- Excavation of 2 shafts, +/- 90 feet deep, using ground freezing method

- Continuous circulation of slurry to remove and dispose of material

- Use of 10” thick precast concrete liner to form the new outfall

- Tie in at the Barrier Island side using a temporary bypass and at the WWTP side through extensive modifications of the piping and pump system

- New gates, valve chamber, meter chamber, chamber 3B, launch shaft, staging areas, mucking area and site work

PROJECT OVERVIEW

This project consists of the replacement of 3 miles of 50-year-old, six-foot diameter, prestressed concrete cylinder piping, laying under the Great South Bay, and facilitating the year-round discharge of the Bergen Point WWTP in the Atlantic Ocean. The means and methods used to accomplish this scope were the construction a new pipe by mining a 10’ diameter tunnel with a 400-foot-long Tunnel Boring Machine in the soft ground, approximately 100 feet below the bay. This required two circular shafts, about 80-100 feet deep, at the plant site and on the Barrier Island, to launch and receive the TBM. Those shafts were excavated and supported using the Ground Freeze method. The outfall pipe itself was built by assembling 10” thick precast concrete liner segments, and continuous slurry to transport excavated material to the surface. Once under way, the operations proceeded 24hrs/day, 6 days/week.

WHAT MADE THIS JOB COMPLEX

Every aspect of this project had its complexities: the outfall pipe could not be taken out of service for any length of time, requiring the use of a “bypass” strategy and relatively rapid tie ins at both ends, using 6-foot diameter stainless steel riser pipes and piping & pump modifications. In addition, to reach the tunnel invert, shafts had to be excavated to a challenging depth of +/- 90 feet. Utilizing the TBM segmental lining technique eliminated the need for an additional carrier pipe, however, required the continuous circulation of a slurry to transport the excavated material to the surface for processing and removal. Once started, the tunneling had to proceed without interruption, 6 days per week, making round the clock shifts necessary. Because shutdowns of the outfall were not an option, the installation of the temporary bypass had to be elaborately planned, especially in view of the questionable condition of the existing PCCP pipe.

HOW POSILLICO SOLVED IT

The key to the success of this project was planning. Most importantly, the use of the bypass allowed the existent outfall to stay in operations. The shafts were excavated using Ground Freezing, wherein pipes are sunk around the perimeter of the shaft and refrigerant is circulated within those, creating a frozen ring designed to withstand external ground pressures during excavation. The segmental lining technique made an additional carrier pipe unnecessary and increased the tunneling efficiency. Given the site constraints at the plant, the size and complexity of the equipment required and the need to minimize impacts to plant operations, developing a plan to excavate the shafts, assemble the 400-foot long TBM and feed the operation during tunneling took a great deal of meticulous planning. Additionally, working three shifts allowed the team to stay in sync with daily deliveries of segmental liners being manufactured offsite.